By Mike Bolduc | August 13, 2018

These days, energy is an important and rapidly changing business, as suppliers are raising prices and consumers are seeking to reduce usage and control costs. The so-called “smart grid” brings huge possibilities, including the decentralization of electricity generation, and intelligent control of energy use. However, smart grid reliability is only as good as the technology that gives it its “smart” credentials.

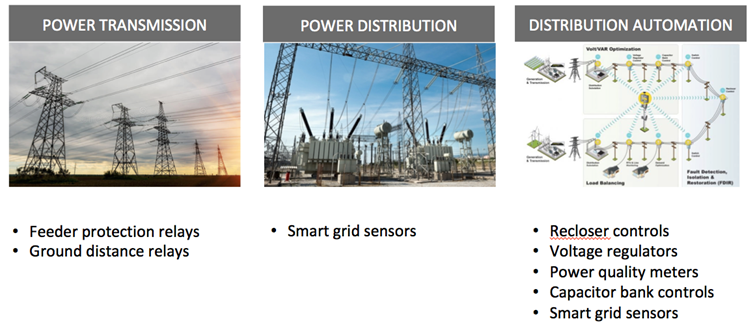

Many types of equipment make up the smart grid, principally in areas such as power transmission, power distribution and distribution automation.

Figure 1: The smart grid is the future of the energy industry

While the equipment is diverse in terms of size and function, it all relies on switches to provide a significant part of the user interface, defining the convenience of operation for all users.

Front-panel switch functions include providing inputs to the system, either alone or in conjunction with a soft menu on a display, as well as communicating with the device, resetting and activating functions – all essential for convenient and reliable operation.

Designer requirements when choosing switches

The process of selecting switches does not always receive the time and attention it deserves. Given the relatively low cost and simple nature of most switches, often they are selected without full consideration of relevant points.

It goes without saying that basics such as the number of poles and throws, latching/momentary action and other electrical parameters are necessary considerations. Also important are the environmental characteristics, and the reliability of the switch – which includes defining the right materials, especially for the contacts, and ensuring that the life cycle is compatible with the expected lifetime of the equipment.

Key to the instrument’s Human-Machine Interface (HMI), the switch’s ergonomics and aesthetics often influence the user’s experience and their perception of the equipment. Haptics – the sound and feel of the switch – are important elements of the switch operation, as they provide feedback to the user to let them know that the switch has been operated. Selecting switches with the correct haptics can give a “high quality” feel to an instrument.

The appearance of the switch can give an indication of its function through the use of color. Groups of switches with similar functions can be identified through color-coding, or switch colors may be chosen to enhance the branding of the manufacturer.

One particularly versatile (and highly configurable) switch that is used in many applications, including smart grid, is the KSC series sealed tactile switch. This single-pole, single-throw (SPST) momentary action push switch is typically used for functions such as display activation and control.

Figure 2: The KSC series switch offers a total of ten actuator options, and other customization possibilities

Designed for small signals up to 50 mA and 32 V DC, the low-profile KSC switch has a body height of just 2.5 mm and is available with ten different types of actuator, making it suitable for multiple applications. Being IP67 sealed, the device is suitable for harsh conditions, and with optional gold over nickel contacts is corrosion resistant and suitable for very low currents. With the gold contacts, the KSC is rated for operation in ambient temperatures between -40°C and +125°C, and for up to five million operations. The compact switch has “J” or “G” surface mount terminations for PCB mounting, and is available in convenient tape-and-reel packaging.

A key, and unique, feature of the KSC is the ability to have the haptics tuned by C&K in its dedicated facility, enabling customers to achieve the right sound and feel for their application.

Summary

The perceived simplicity of a simple push switch often leads to it being overlooked during the component selection/design process, with designers only considering the basic functional parameters. However, switches are integral to the HMI and are often the only part of equipment that is touched by a user, thereby defining the perception of the quality of the equipment.

Intelligent selection of color can make the equipment more intuitive to use, and reinforce marketing branding – and it requires very little, if any, extra expense. The materials used for the actuator and the sound and feel of the switch when pressed and released have a big impact on the user’s perception of quality, and selecting the best haptics for any particular application can bring significant benefits, including positive feedback on the switch operation and confidence in the equipment.

C&K Switches is leading the way in developing custom haptics for a very wide range of applications, and can develop the exact sound and feel required for any application in its dedicated laboratory. Once a specification is settled on, this design can be replicated consistently in any of C&K’s global factories.

Mike Bolduc

Global Segment Manager

Industrial